Transparency in product costing through the use of SAP Analytics

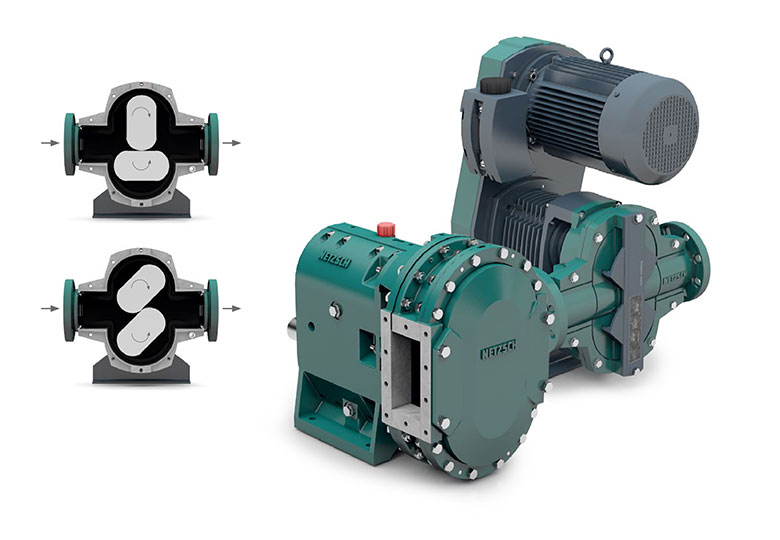

Sectors: Mechanical and plant engineering

Processes: Analytics

References: NETZSCH

The current economic climate is posing a host of issues for many companies. Examples include increased freight costs caused by global disruption to supply chains and fluctuating prices for raw materials and purchase parts as a result of current inflationary pressure.

To address this problem, NETZSCH Pumpen & Systeme has teamed up with Saarbrücken consultancy firm ORBIS SE to implement an innovative solution for the analysis of its costing data. NETZSCH Pumpen & Systeme has already been using SAP S/4HANA to cost its pumps for years, using the costs calculated not just to set its sales prices, but also to evaluate its material stocks at any given time.

Sector: Mechanical engineering

Production sites: Waldkraiburg in Oberbayern

Products: Rotary positive displacement pumps from screw pumps, rotary lobe pumps and progressive cavity pumps to peristaltic pumps, including associated digital services

Employees: more than 4,000 (2022; NETZSCH Group)

Website: www.netzsch.com

The variety and complexity of the materials it produces makes it difficult to analyze the costing data accumulated in SAP S/4HANA. For that reason, NETZSCH Pumpen & Systeme has opted for a custom analysis solution based on SAP Analytics, with SAP BW on HANA used as a data warehouse, and SAP Analysis for Microsoft Office as a frontend. All information gleaned from the multi-level itemizations from the SAP S/4HANA product costing are replicated in the data warehouse where they can then be analyzed using a top-down or bottom-up approach.

As part of the top-down approach, the costings for all materials are aggregated by different material attributes and compared in time series. This makes it easy to ascertain which finished goods product categories have seen the biggest cost adjustments. The user can focus on these product categories and analyze the respective role input materials and internal labor have played in the cost increases – and access all parts list levels right through to input materials in the process.

Source Photo: © Erich NETZSCH GmbH & Co. Holding KG

Vice versa, the bottom-up approach involves proceeding to find out which end products have been affected by adjustments to the cost of an input material or a rate for a type of service. Identifying problematic cost increases allows swift analysis of which end products have been affected, and to what extent. This information serves as a means of responding to cost adjustments ahead of time.

Introducing this Analytics solution has enabled the company to start analyzing costing data efficiently in aggregated form and mapping the effects on sales prices, enabling NETZSCH Pumpen & Systeme to assert and expand its competitiveness in international business.

NETZSCH Pumpen & Systeme has been an ORBIS SE client for years and is assisted by ORBIS SE in the fields of SAP S/4HANA, Customer Experience, SAP & Microsoft Analytics.

Source Photo: © Erich NETZSCH GmbH & Co. Holding KG